Laser Automation

SmartFlex Rapid Series

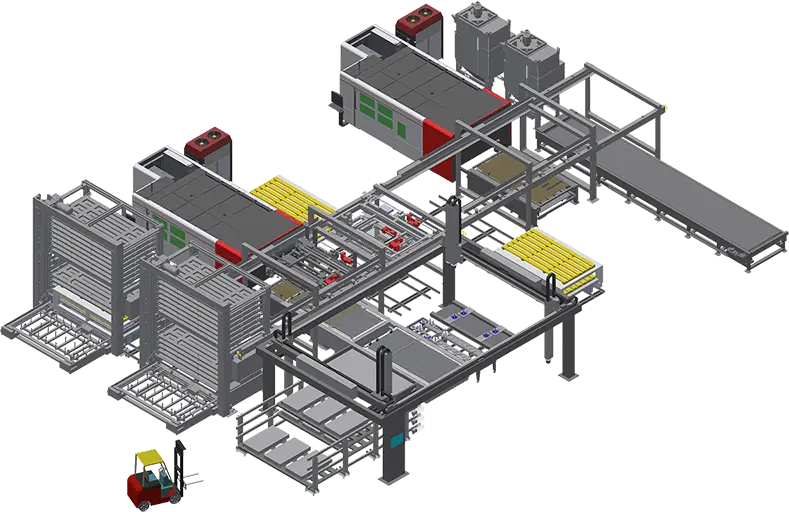

Truly taking advantage of today’s faster lasers and improved software requires an automation solution that keeps up. Mitsubishi’s answer: the SmartFlex Rapid Series Automation, sporting an industry leading 52 second sheet cycle time (3015). All Rapid automation systems feature a flow-through design that separates cut nests from raw material, getting parts on their way faster and easier.

The Rapid Series’ unmatched speed, expandability, and true lights-out reliability opens the door to confidently grow and service a multi laser line. From simple single laser systems to triple laser lines outfitted with nest conveyors, AGV’s, or part sorting, Rapid automation is fully modular and can be configured to fit your shop’s needs and accommodate for future growth.

Astes4 Systems

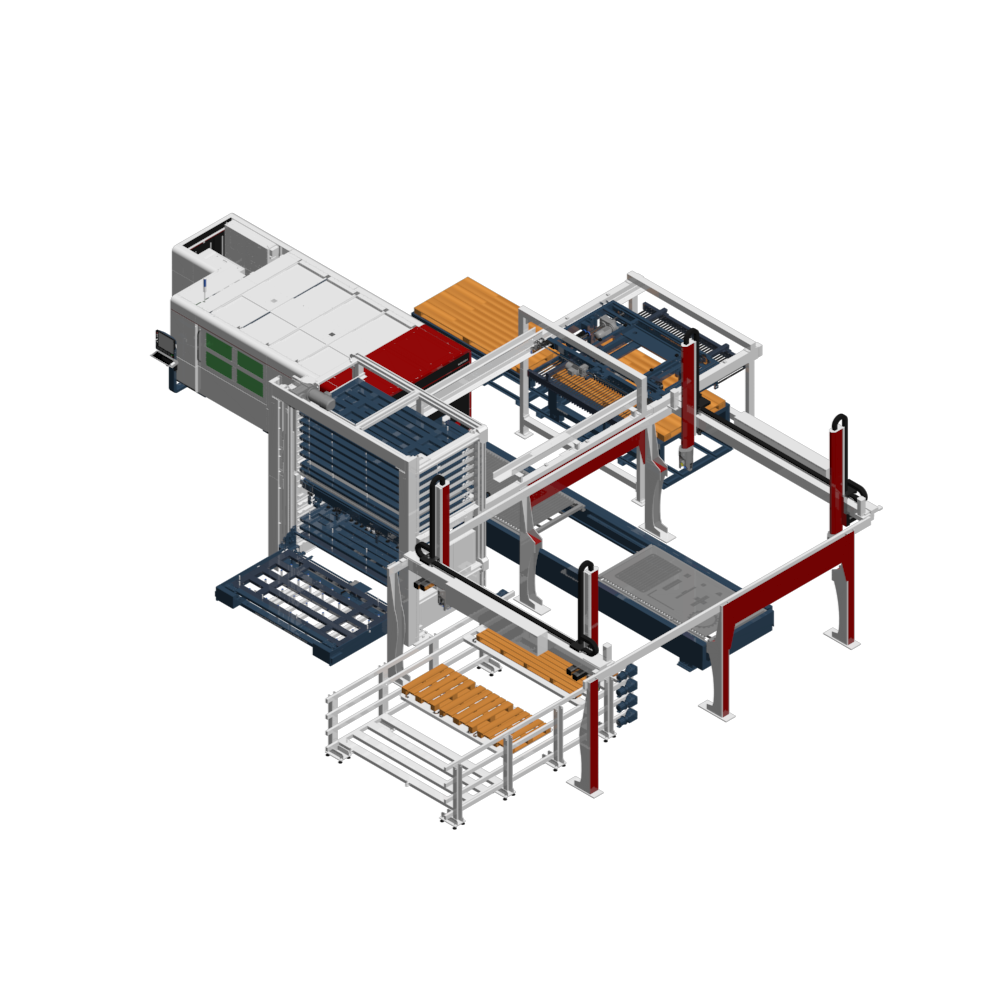

In most shops, the breakout area is the biggest production bottleneck, making the speed of today’s fibers irrelevant with parts stuck sitting in a stack of nests. That’s where Astes automation comes in. Astes is the industry’s leading automated denesting and part sorting solution.

Astes automation is far more flexible in the part sizes and weights that it can handle compared to competitive solutions, and it gets the job done faster. The 4 in Astes4 refers to the patented configuration of four independent gripper heads spanning two gantries, a design that maximizes offloading speed and boosts the overall lift capacity of the system when multiple heads lift a part. Like all other Mitsubishi Automation, Astes4 systems can be laid out in configurations and capacities that match with your production demands and future growth.

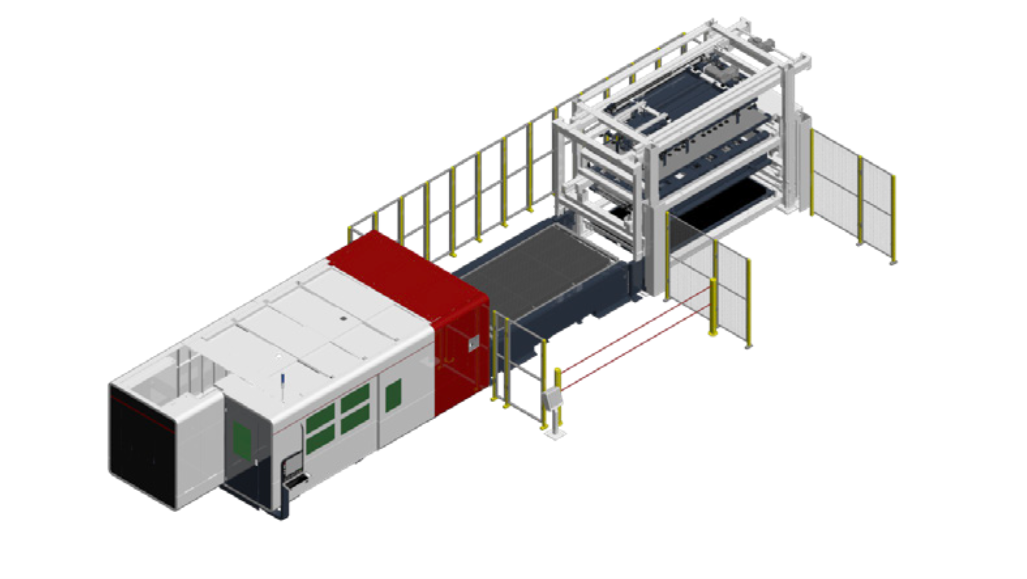

Compact Automation

Floor space is at a premium in most shops, making the larger footprint of systems like the Rapid a tough fit. Mitsubishi offers a range of automation options that deliver the productivity benefits of automation in linear or single-sided layouts. These compact automation systems can dramatically increase laser up-time and add lights out capability, while preserving the flexibility and machine access that high-mix short-run shops need. Despite their smaller footprints, these systems include the best features of Mitsubishi automation like unmatched sheet-to-sheet cycle time and the flexibility to retrofit to a standalone laser, swap in new lasers to existing systems, or expand.

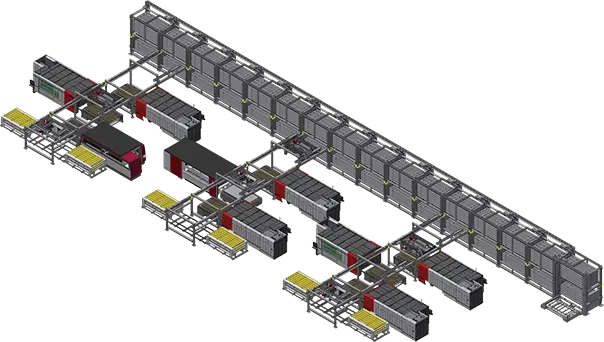

SmartFlex River System and Custom Solutions

River Systems are the shopfloor backbone at some of the largest manufacturers in the industry. A River links automated storage and retrieval (ASRS) to branching laser lines, bringing material receiving and inventory tracking online with production and job scheduling, all in one seamless system. Like other Mitsubishi automation, River systems are modular and expandable, and can be configured specifically to fit the space and application.

Mitsubishi’s standard automation solutions are best in the industry, but these can also be customized to suit a shops needs or in some cases lead to the design of an entirely new system based on a customer’s goals. For example, one Wisconsin customer had Mitsubishi design a system that automatically removes nest skeletons from its dual laser line. Skeletons are offloaded to a conveyer and sent right out of the building into a dumpster without extra handling. If you have a special application or goal, Mitsubishi is ready to listen!