Keeping Production Moving: A rundown of automation conveyor applications and productivity benefits

12/27/25

While automated sorting systems like the Astes have attracted the most attention in recent years, conveyors have quietly become the go-to denesting solution for many Mitsubishi Rapid series automation owners. Conveyors offer several advantages over systems that rely solely on nest carts, or those that return nests to a tower.

Denest in real time. A denesting crew can pull parts from a freshly cut sheet and send them to their next operation, rather than waiting for a stack of nests and hours of pulling parts in a seperate breakout area. Most shops with conveyors simply denest right off the conveyor and then the automation deals with the skeleton.

Quality Improvements. Handling nests one at a time is leaner and easier on those doing the denesting, but it also has quality benefits as well. A cut quality issue gets noticed right away with real time denesting and can be corrected for the next sheet. Denesting from a conveyor also minimizes scratching that commonly occurs pulling nests from a stack.

Flexible for changing demands. You can send more or fewer jobs to the conveyor as needed on the fly, and always have the option of offloading to nest carts when unmanned. Conveyors don’t reduce your offload capacity, only adding the option to quickly attack denesting and streamline you laser area when you have the staff there for it.

Full Automation Integration. Conveyors are configured as a full component of the automation, not some aftermarket add-on. Control which sheets flow to a conveyor using the automation shop floor line control software. Optional Ncell “MX” denesting software can display color coded parts, next operation, and other useful information for crews at the conveyor on an overhead screen. Data returned to the office improves part traceability. Safety light curtains are standard.

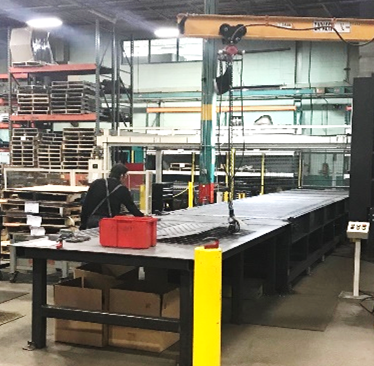

Three workers tend to this conveyor, which draws from two fibers.

Slat conveyor with adjacent table & overhead jib crane.

Conveyor Details:

New London Conveyor – Laser conveyors needs to be heavy duty to stand up to the breakout process. Mitsubishi uses conveyors from Wisconsin’s own New London Engineering, known for their durability and reliability.

Conveyor Sizes/Styles

- 5’ x 10’ (3015), two or three blank capacity, ½” rubber belt or 1” capacity steel slat.

- 2m x 4m (4020), two or three blank capacity, ½” rubber belt or 1” capacity steel slat.

- Slat conveyors available with optional rubber inserts (below) to reduce the clearance between slats.

Conveyors are available in both slat style and rubber belt, 3015 and 4020, two and three blank lengths. There are plenty of conveyor suppliers building solutions for places like amazon warehouses, but few make them like New London.

Conveyor Equipped Automation Options:

Conveyor Only Systems – Some might question why anyone would buy automation if the laser couldn’t run unattended. “You might as well and just pull parts and skeleton off the shuttle table”.

But that’s not an easy task and a common source of injuries. Also, an automated laser with conveyor has a much higher beam-on percentage than a manually operated shuttle table laser. The conveyor sets the pace of the cell, not your operator.

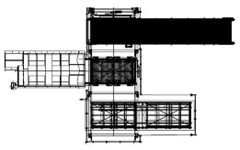

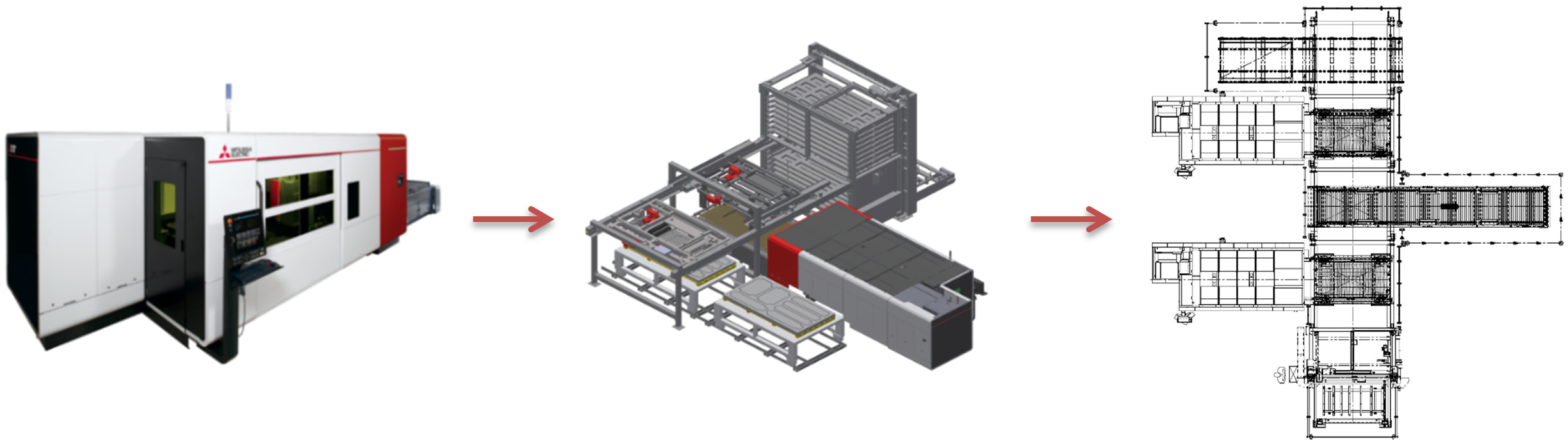

Rapid with 2 material carts (skid compatible, 11,000 lbs. cap. each) and a 3-blank nest conveyor.

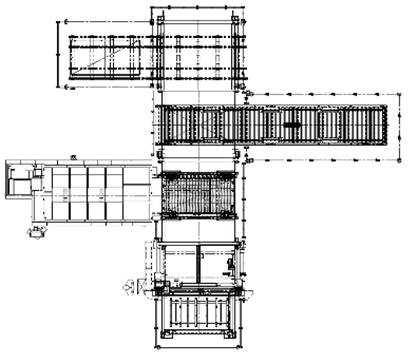

Rapid Tower with a 2-blank nest conveyor.

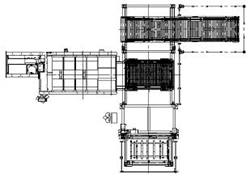

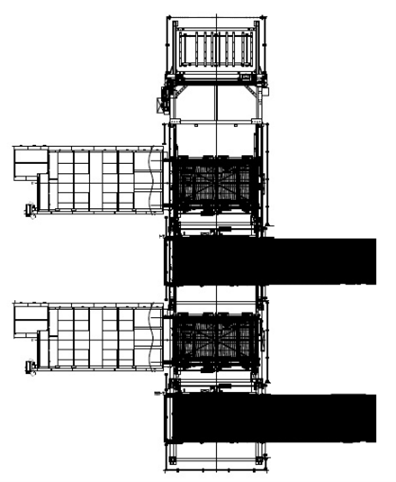

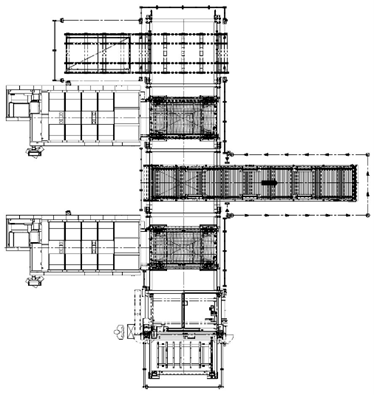

Rapid Tower (reverse flow) with two 2-blank conveyors.

Conveyor with Cart Systems – allow nests to flow to a conveyor (or conveyors) during manned shifts, and to carts when unmanned. While unloading nests from skid compatible carts is more cumbersome than a conveyor, it still beats having to dig nests out of a tower.

Many are successful using one 3-blank conveyor for two lasers. Others prefer one per laser. We can run a nest run time simulation so you can make the best choice for your application.

1 laser, 1 conyeyor, 2 carts

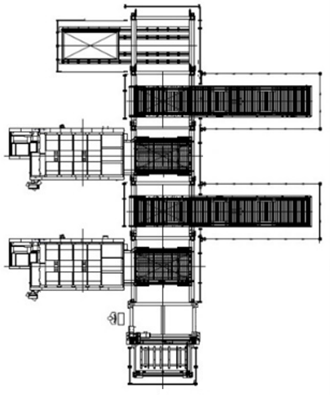

2 lasers, 1 conyeyor, 2 carts

1 laser, 2 conyeyors, 2 carts

Building Block – For example, you could start with a shuttle table laser, later add a Rapid Tower with nest carts, and then expand to a second laser and nest conveyor servicing both lasers. What you end up with is identical to a system installed turnkey. And Mitsubishi automation is built to last, capable of accommodating a second generation of lasers within the same line.

In summary, Mitsubishi’s Rapid series automation equipped with a conveyor makes denesting a less daunting process. Your material handlers will pull more parts, reducing the denesting bottleneck. If you don’t have the space or budget for automated sorting, it’s a great option.