River System

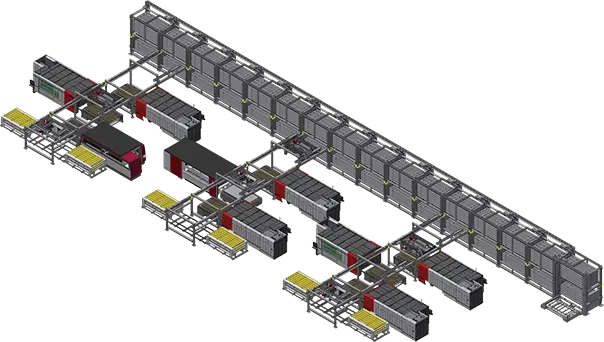

An automation solution with virtually unlimited storage capacity, the River System is fully customizable to fit a shop’s specific needs. River racks integrate material storage into production and shop scheduling, minimizing handling between material delivery and cut parts.

A River system improves production by cutting out idle inventory and making material receiving and storage the first part of your automated laser line.

The system can be configured to simply store and retrieve material to nearby work stations, or integrated with Mitsubishi lasers and Rapid automation gantries.

River systems are configured specifically for a customer’s floorspace and application. And because Mitsubishi automation is modular and retrofittable, new lasers and laser lines can be added to a River, as well as swapping in new generations of lasers with minimal downtime.

River System Details:

- Rivers are made up of multiple connected material towers or bays all accessed by a monorail and material elevator that retrieves shelves and delivers them to a laser line. The clip at right shows a dual sided River in action.

- Configurable with laser lines off of any bay to fit specific floorplan and shop workflow.

- Max 25 shelves per bay

- 6,600lbs per shelf, 1″ full sheet capacity

- Expandable with additional bays and laser lines.

- Up to three lasers per line.

- “Line Control” automation software simplifies and choreographs production. Shops with River systems spend fewer hours scheduling per laser and gain greater visibility across their operation.

Custom Automation Solutions

Hatco Astes Presenatation

Hatco is an innovator in laser automation, integrating Astes automated part sorting into their dual sided River with the option of offloading to AGVs. This presentation gives a sense of what’s possible with our automation and their plans for future growth.

Looking at Mitsubishi’s automation offerings, the words “modular” “flexible” and “expandable” may start to get old, but it’s the truth. No one else in the industry comes close to the range of automation configurations Mitsubishi offers, or their ability to update and expand systems.

This flexibility and modular design approach enables us to customize systems and layouts within our automation lineup, or in some cases design an entirely new system to fit a customers needs. For example, a Wisconsin customer had Mitsubishi design a system that automatically removes nest skeletons from its dual laser line, rather than loading to carts. They go right out the building and into a dumpster.

Whether it be a custom layout given space constraints, lights out integration with next operations, or a goal of minimizing denesting backups, we are happy to work with you to design a solution.