Compact Automation

The Compact Automation series includes modular, space-saving, material-handling systems that deliver capable and expandable automation for shops of any size. With small footprints, Compact Automation maximizes productivity in minimal space and makes automation practical even for short-run job shops.

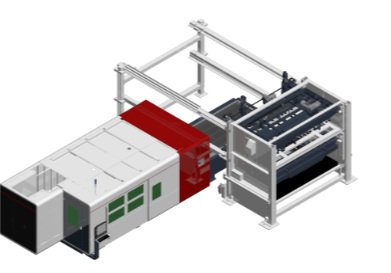

Compact Plus

Flexible, expandable automation with a small footprint. The Compact Plus delivers the productivity and efficiency gains of automation in a streamlined and reliable package. The 3015 system footprint is 32’ x 42′, great for for small areas or against a wall. Like the rest of the Mits Automation lineup, layouts can be reconfigured to fit with your shop floor.

- Small, single-sided, layout great for shops low on space.

- 1 load and 1 unload shelf, each 6600lbs capacity.

- Completely modular and expandable. Later add a tower, 2nd laser, nest conveyors, and additional pallets.

- Full load/unload cycle in 75 seconds (3015).

- Automatic thickness detection and double sheet separation standard. Sheets pre-positioned at 0.0 by automation for faster cycles between sheets.

- Finished goods pallets are always located below raw material to make sure falling slugs don’t interrupt operation.

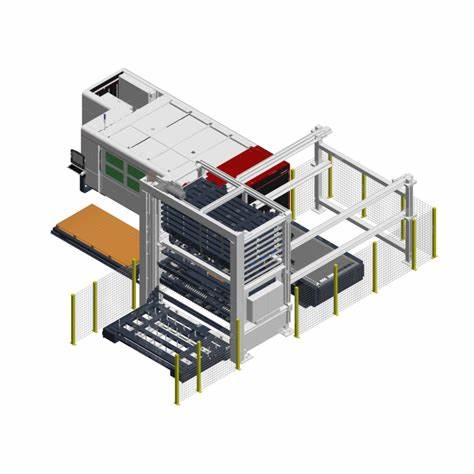

Compact Plus Tower

All of the benefits of our Compact system with greatly enhanced storage capacity for uninterrupted production. Towers add 6 to 14 (3015) or 6 to 12 (4020) shelves of storage at 6600lbs capacity each, with barely more floor space. The Compact Plus Tower can store both raw material and finished goods for hours of lights-out production. Other layouts feature alternative layouts for manned and unmanned production.

- Single (6-14 shelves for 3015, 6-12 for 4020) and dual tower systems (up to 34 shelves) available.

- Tower is retrofittable and expandable with more shelves

- Full load/unload cycle in 75 seconds (3015).

- Line Control software keeps it easy. Software tracks material in the tower, next jobs, and completed nests.

- Two tower loading stations – For dual laser systems a second tower load station saves time tending two machines running dissimilar sheets.

- Automatic thickness detection and double sheet separation standard. Sheets pre-positioned at 0.0 by automation for faster cycles between sheets.

- Finished goods pallets are always located below raw material to make sure falling slugs don’t interrupt operation.

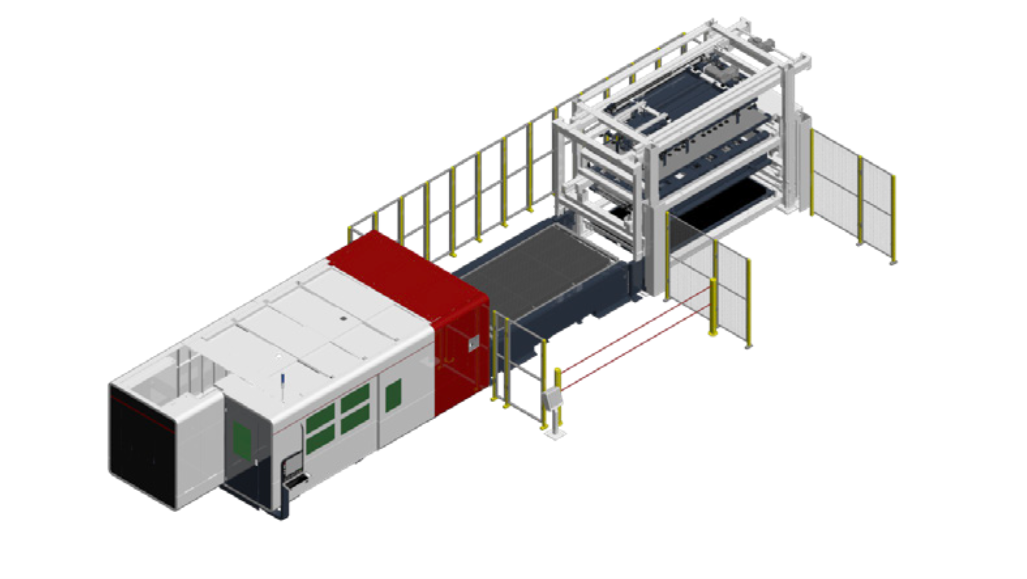

Element Type R

Ideal for smaller shops or small spaces, the Element Type R allows you to take advantage of the productivity of automation in a space-efficient package. The linear footprint allows positioning against a wall and shuttle table access means you can manually load a hot job then quickly transition back to fully automated production.

20’x53’ footprint (including laser) ideal for narrow spaces.

- Comes standard with two load pallets and one floor located offload station.

- 95 second load and unload cycle time.

- Vacuum load with thickness detection, sheet separation, and Aerial Positioning.

- Robust ¾” sheet capacity.

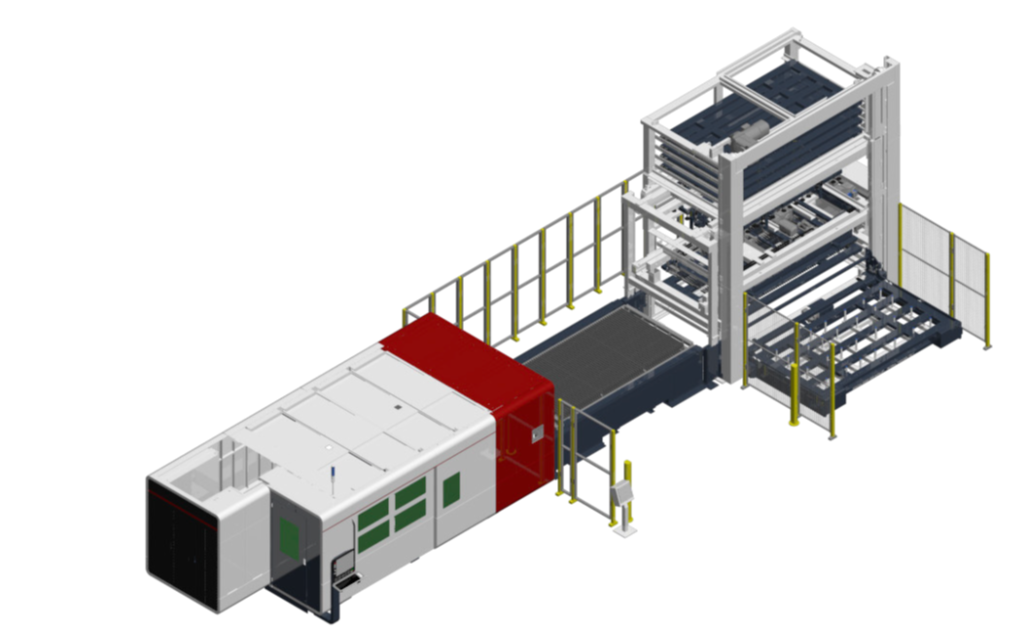

Element Type R Warehouse

The Element Type-R Warehouse adds additional storage to the compact and capable Element system. Choose configurations from 6 to 14 material shelves to expand your lights out capacity and bring material off the floor and into production. The space-saving 20’x53’ Element footprint remains virtually unchanged and the Warehouse tower can be retrofitted at any time.

- 20’x53’ footprint (including laser), with added storage shelves, ideal for increasing storage in narrow spaces

- 95 second load and unload cycle time

- Vacuum load with thickness detection, sheet separation, and Aerial Positioning

- Robust ¾” sheet capacity

- Six shelf standard. Expandable with additional midframes.

- Fully retrofittable to standalone lasers.