Astes4 automation are fully integrated systems for material processing, sorting, and storage. Mitsubishi acquired Astes4, the global leader in automated denesting, to deliver the best multifunctional automation systems for material handling and part flow. Available as a standalone production cells as well as fully customizable and expandable multi-laser lines.

Key Astes Features:

- Full Sheet 1.0” Load/Unload Capacity

- Fast – The Astes is typically waiting on the laser, not the other way around.

- Six Sorting Tools in Each Arm – Pick a greater range of parts with different end effectors. This also further decreases sort time since the arms don’t have to swap tools between picks.

- Heavy Duty – 160 lbs. per arm, 640 lbs. of lifting capacity when all four used at once. Higher capacity systems available.

- Single Source Support – Astes can be installed on other lasers in Europe, where it is the most popular sorting option for Trumpf and Bystronic users. But Mitsubishi has decided to just focus on Mits lasers in North America to insure an optimum user experience. No waiting on a support call from Europe either, Astes service and support for the U.S. are based at Mitsubishi’s Illinois headquarters.

- Don’t Need to Sort Everything – Due to size, part geometry, or run quantity, you may not want to run everything through the Astes. No problem – intact nests can be directed to flow to a nest cart.

The Astes Advantage

Patented 4-arm System – Critical for Nesting Flexibility and Yield:

- Up to four parts sorted at one time.

- Multiple arms for large, long, or drooping parts.

- Part rotation. Use arms from either gantry to rotate the part during the sort operation. A two arm system can only nest/sort/stack longer parts in one direction, which restricts dynamic nesting.

Astes Knows Part Weights – The system varies the degree of magnetism to only apply the required lifting force. Different size suction cups have different pull strengths. Thus, if a part is welded into a sheet it doesn’t lift the entire nest and create a mess

SortCam Does the Thinking for You – Using a nest program, Astes software determines a part’s center of gravity, optimum pick point and tool, and how much it will flex. Too much flex and it determines that two or three pick points are needed instead of just one. SortCam runs in the background and computes a denesting and part sorting program for a nest on the fly. Competitive systems can’t do this, and you may need to program an entire denesting system on your own.

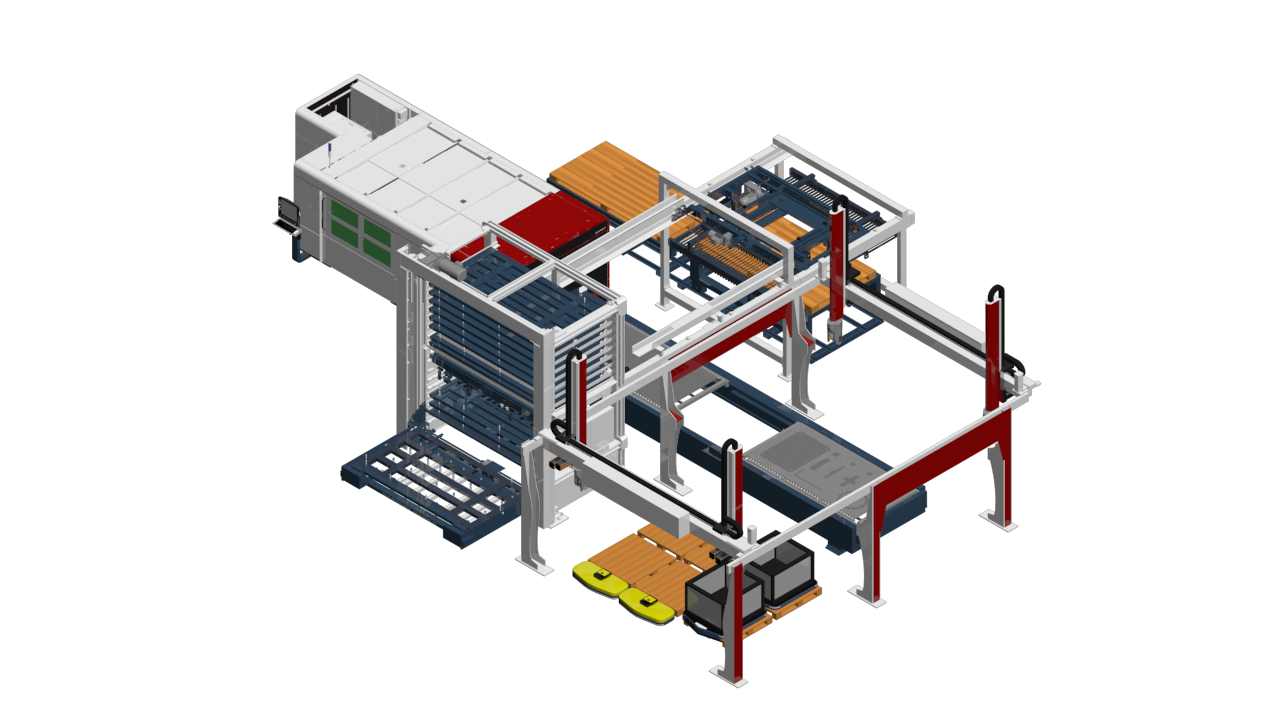

Astes High Speed Advanced

The ASTES4 High Speed Advanced is the perfect solution to production bottlenecks resulting from the increased productivity of higher-volume fiber lasers. Simultaneously managing material handling and part sorting, this automation can keep up with your high volume production needs.

- Available in 3015 and 4020. Customizable and modular layouts.

- Sorting heads feature six end effectors in each sorting head and four arms to pick heavy parts or challenging geometries. Few parts can’t be sorted.

- Made for dynamic nesting – Most shops don’t run the same nests. With Astes that’s not a problem. SortCam handles the sorting programing with just a nest file. Four arms can handle part rotation other systems can’t.

- No laser idle time – Three pallets, Rapid Automation, and the speed of the Astes mean there is never a moment without material cutting.

- Ready for lights out operation – A pallet sweep clears slugs and unattended modes that modify pick points for added confidence make lights out runs possible.

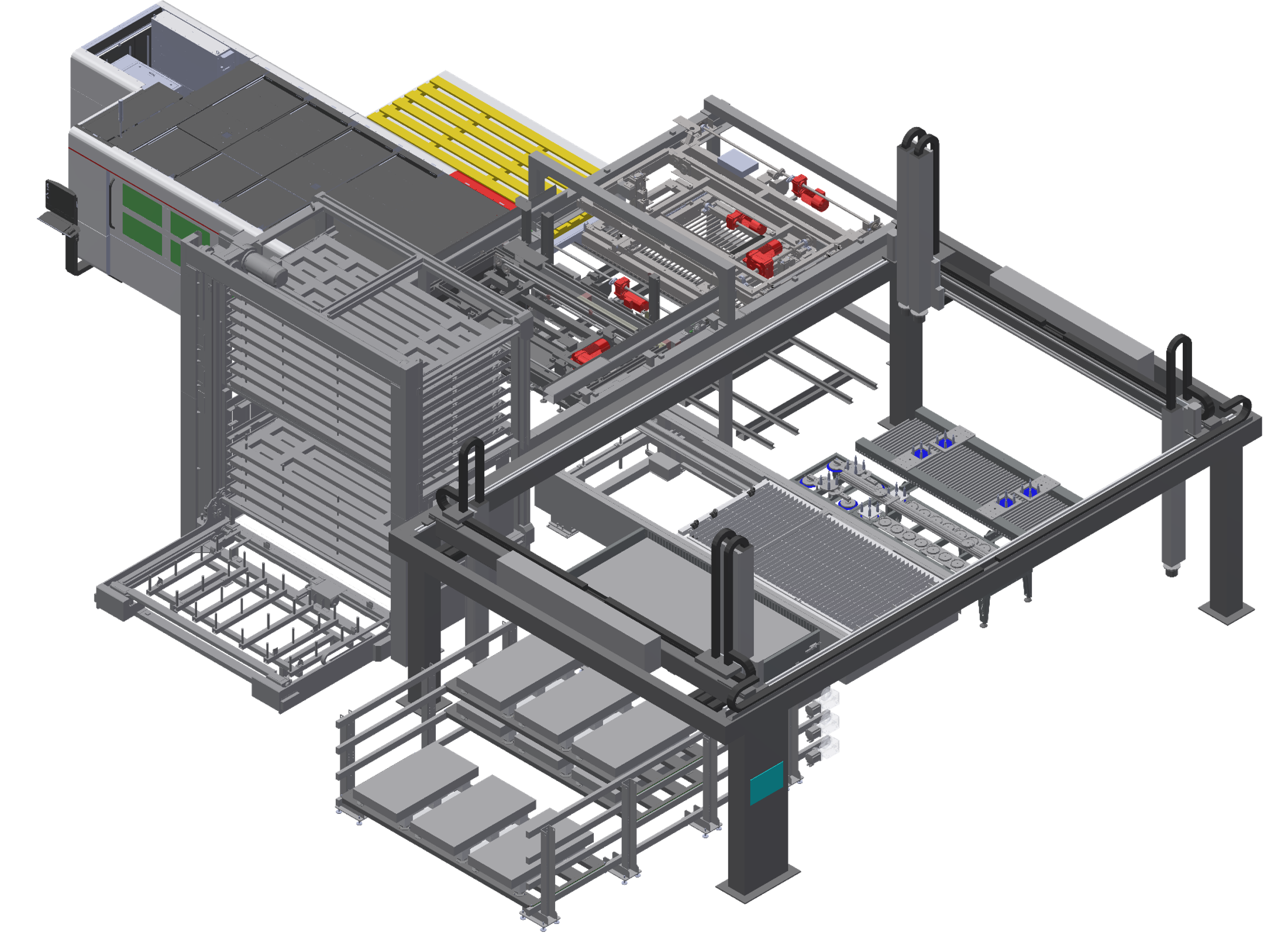

Astes Sort Advanced

The Astes Sort Advanced pairs the industry-leading technology of Mitsubishi’s RAPID Automation with the higher capacity Astes Sort. This system provides the ultimate solution for denesting large and heavy parts quickly and safely. Together the four arms can lift over 2000 lbs.

Like in the Astes High Speed, finished parts are sorted independently of the laser system and automation gantry on a third pallet. This means that while a sheet sorts, another is cutting and a third is being loaded, allowing the system to continually run even during fast cycle times. No other system available on the market can do that!

Heavy Duty sorting ready for full sheet parts. Eliminate hammers, pry bars, and jib cranes for denesting large parts.

- Offload to four shelf part vault, or add conveyors, AGVs.

- SortCam software computes sorting program from just a nest file. Easily sort new nests and parts.

- Available as 3015 or 4020. Base system features material tower, skeleton carts, pallet sweep, and four position offload vault. Customizable layouts and expandable with additional material storage or multi-laser lines.