Rapid Series

High throughput, fast, and always available, RAPID series automation is the shop floor QB at the industry’s leading shops, and for good reason. Ultra-fast high wattage lasers and features don’t matter if the automation isn’t reliable or can’t keep up. If you are looking to increase production, confidently run lights out, and experience less down time, then Rapid automation should be the cornerstone of your automated laser system.

Rapid Series Innovations : Speed and Efficiency

- Sheets Pre-positioned on the Table – No need for the laser to waste time “finding” the sheet perimeter. Once the sheet shuttles into the laser its ready to begin cutting.

- :52 Second Nest Unload/Sheet Reload Cycle – Means that if you had a run of nests that took just a minute to cut, your lasers would not be waiting on the automation.

- Multi-tasking Unload/Reload – The two mechanisms traverse the same gantry but are independent, ideal for tending two lasers at the same time.

Maximum Throughput

Flow Through Architecture: Some automation systems feature designs where cut parts flow back to a tower that holds both raw material and cut nests. But digging nests out of a tower is a hassle, parts can fall out of the nest, etc. In contrast, the Rapid Series gets parts on their way, sending them directly through to motorized carts, conveyors, or a combination of the two (as pictured here).

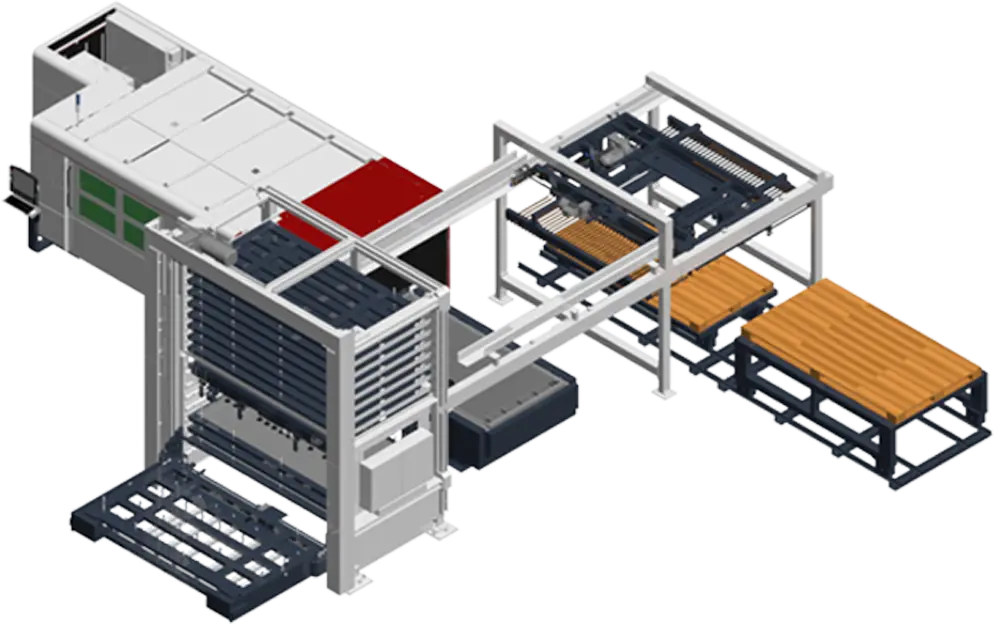

Rapid Base

The foundation of the Rapid series – Load from two high capacity carts for a total of 22,000lbs of raw material capacity. Offload nests to an identical set of carts. Sheet separation, thickness detection, aerial positioning, and an industry leading 52 second cycle time are all standard.

Details

- High capacity dual cart load and unload.

- Modular and expandable. Add a tower, a second laser, conveyors, etc. without scrapping the existing system.

- Simultaneous, high-speed loading and unloading. Load and unload units travel independently for faster operation.

- Quickly transition between scheduled work and a hot job. Out position material cart is easily accessed to load material between scheduled nests.

- Compatible with smaller sheet sizes.

Rapid Tower

The Rapid Tower is Mitsubishi’s most popular automation configuration, and for good reason. First among these is reliability. Customers have gone decades running Rapid Tower systems, swapping in multiple lasers in that time. The Rapid Tower pairs all the benefits and cycle speed of the Rapid Base paired with the ability to store and run more material. Cut nests on a Rapid Tower flow to motorized carts, conveyors, or a combination of the two, no digging around the tower to retrieve a nest.

Tower Benefits:

- Eight to twenty-two shelves of storage (20 for 4020). Over 150,000lbs of material.

- Second load station allows simultaneous material preparation, an asset in multi-laser lines unique to this system

- Heavy-duty 1″ full sheet capacity.

- Pallet sweep option removes slugs between sheets.

- 6,600 lbs load capacity per shelf

- Dual tower layouts with up to 46 shelves (32 for 4020) available.

- Customizable layouts and options like offload conveyors, additional carts, reverse orientations.

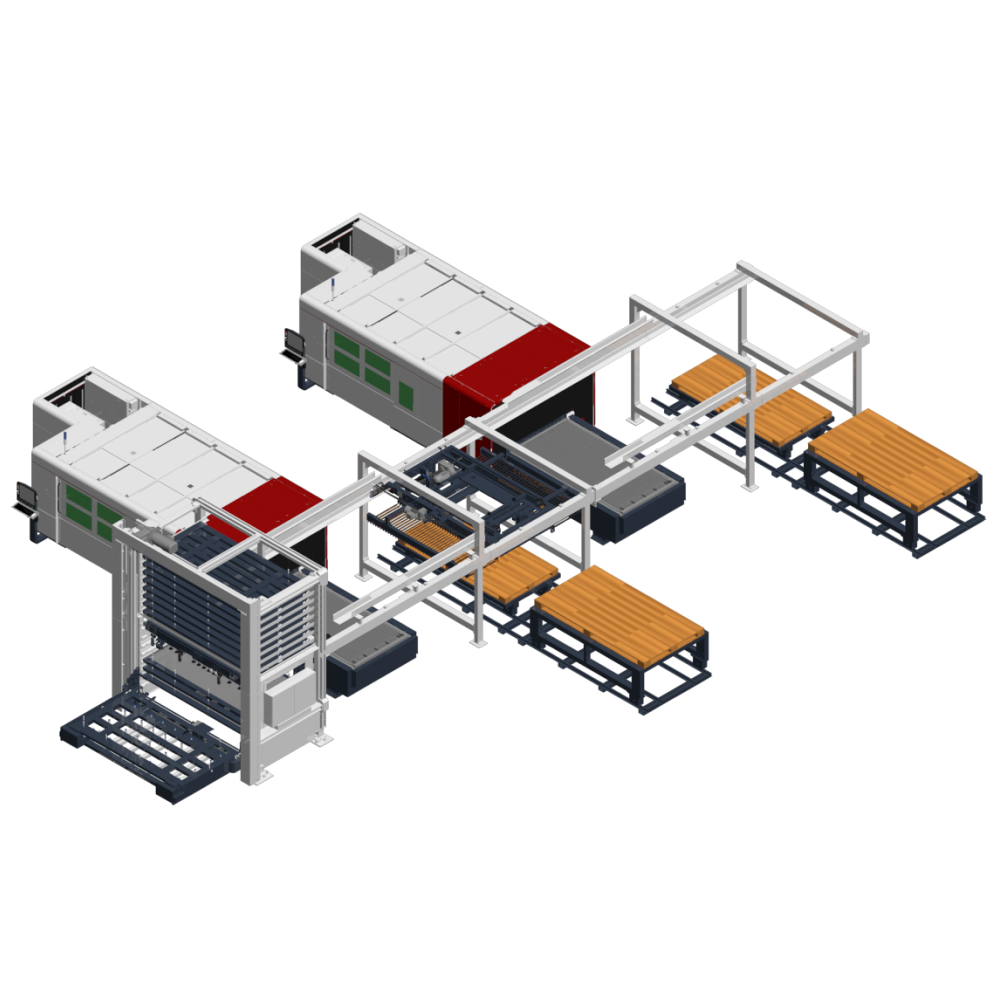

Multi-Laser Rapid Tower

As your operation expands, Rapid series automation can grow with you. Installed turnkey or built piece-by-piece, multi-laser lines maximize efficiency, floor space, and productivity. Unique features like independent load and unload units and a second material loading station in the tower mean the lasers are never waiting on the automation, even in triple laser lines.

Details

- Multi Laser Flexibility – Start with a base system and later expand with a tower and 2nd laser. Nests from either laser flow to carts or a conveyor during manned hours, and to carts when unmanned.

- Reliable – Our laser customers have more multi-laser lines than not, often putting new fibers into older systems like this triple line.

- Easy Programming – “Line Control” software keeps track of scheduled jobs, material in the tower, and completed jobs. Competitor’s automation systems need you to hire a new engineer to run them.