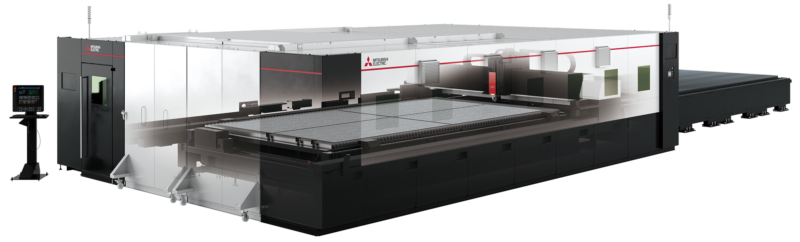

GXL-F Series Fiber

The GXL-F builds on the foundation of its XL-F predecessor with more power and the addition of process monitoring and cost saving features introduced in the GX-F.

Process four 5’x10’ sheets on one pallet thanks to the extra large 10′ bed width. With machines up to 10’ x 26’ and modern fiber features like Advanced Gas Reduction and AI process monitoring, the GXL-F offers maximum versatility.

The GXL-F makes the precision and production speeds of smaller fibers available for processing large, wide, or irregular workpieces. Stand out with the capacity to process sheets over 13′ and eliminate additional fabrication and weld seams. The unique 10-foot bed width also means you can load 8 standard blanks for hours of uninterrupted cutting. The shuttle tables are full sheet 1.25″ capacity and built to take a beating.

- Mitsubishi Single Source Fiber Oscillator

- AI Process Monitoring – Tweaks cut conditions on the fly to improve edge-quality and cut-speed.

- 21 Position Nozzle Changer with nozzle life monitor.

- Advanced Gas Reduction (AGR) reduces assist gas consumption across material types.

- Multiple Sheet Detection & Scheduling – Press start once and run 8 different sheets with different nests.

- Remote 360 machine monitoring – Track production stats, diagnostics, and laser status online and offsite.

- Easy to operate and learn, intuitive touch screen control.

Specs

- Available in 10′ x 20′ and 10′ x 26′

- 6kw to 20kw