Diamond BH

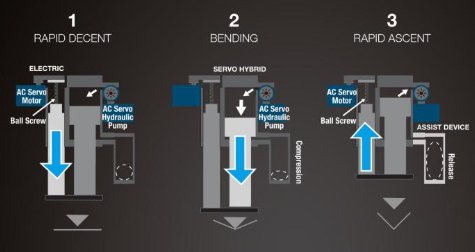

The Diamond BH dual-drive system:

- High speed up/down ram movement done using electric ball screw drive.

- Once at pinch point, a servo-hybrid hydraulic system takes over for bending movement and tonnage .

- Ram retract is assisted by a gas accumulator that springs ram up, reducing wear.

Why Buy the Diamond BH Series?

Mitsubishi’s Diamond BH is the industry’s highest tonnage ball screw driven brake, the best drive system for accuracy and speed. Trumpf’s 7000 series is available to 60 tons, while Amada’s EGB tops out at 143 tons. Diamond BHs are available up to 275 US tons at 10 ft or 4 meter.

Patented Dual Drive – Step on the pedal and you’re at full torque as ball screws drive the ram to pinch point. There’s a seamless transition to hybrid hydraulics to deliver the forming tonnage. But that’s it. The servo driven ball screws do the rest, both during descent & lifting the ram.

No Upper Beam Hanging Weight – A sealed, maintenance free N2 accumulator cushions the ram when idle and pops it back up during retract. This is how ball screws can drive the ram up and down, even on the BH-2504 which has a shipping weight in excess of 50,000 lbs.

Quiet, Reliable, Low Maintenance, Low Cost of Ownership – 1.2 kilowatts per hour average electrical draw. Seals projected to last 16 years because the hybrid hydraulics see such little use.

BH 8525

Benefits:

- Unique ball screw hybrid design brings unmatched responsiveness and accuracy to higher tonnage machines:

- 1-micron repeat accuracy

- Fastest cycle time in its class

- Patented automatic micro-wedge crowning system comes standard. Crown automatically adjusts for off-center and stage setups.

- Standard 5-axis back gauge on 2.5/3m (telescoping X’ and twin tower style 6 axis backgauge available)

- Pulse handle with axis control & bending support

Details:

- Cycle Time: 2.3s

- 1565 strokes per hour

- Bending Length: 94″

- Distance between frames: 87″

- Open height: 21″

- Ram Stroke: 10″

BH 13530

Benefits:

- Unique ball screw hybrid design brings unmatched responsiveness and accuracy to higher tonnage machines:

- 1-micron repeat accuracy

- Fastest cycle time in its class

- Patented automatic micro-wedge crowning system comes standard. Crown adjusts for off-center and stage setups.

- Standard 5-axis back gauge (telescoping X’ and twin tower style 6 axis back gauge available)

- Pulse handle with axis control & bending support

- Videre compatible

Details

- Cycle Time: 2.3s

- 1565 strokes per hour

- Bending Length: 122″

- Distance between frames: 87″

- Open height: 21″

- Ram Stroke: 10″

BH 2504

Benefits:

- Unique ball screw hybrid design brings responsiveness and accuracy to higher tonnage machines

- 1-micron repeat accuracy

- Fastest cycle time in its class

- Patented automatic micro-wedge crowning system comes standard. Crown adjusts for off-center and stage setups.

- Standard 7-axis back gauge (telescoping X’ backgauge option available)

- Pulse handle with axis control & bending support

- Videre compatible

Details

- Cycle Time: 2.3s

- 1565 strokes per hour

- Bending Length: 161″

- Distance between frames: 146″

- Open height: 21″

- Ram Stroke: 10″

Videre Operator Assist

Videre is a retrofittable option for Diamond brakes that provides operators with useful information like bend sequences, tool setups, and part files projected right on to the ram of the brake.

Operators can run through the bend steps for a new part in real-time, improving safety and reducing mistakes. Operators can also use Videre for tooling setups by projecting tooling profiles above the clamping. Programing for Videre is easy too, if you have an offline part program you have a Videre program as well.

Available as an option on all BH series Diamond Brakes, as well as the BB6020.