Acieta FastBend

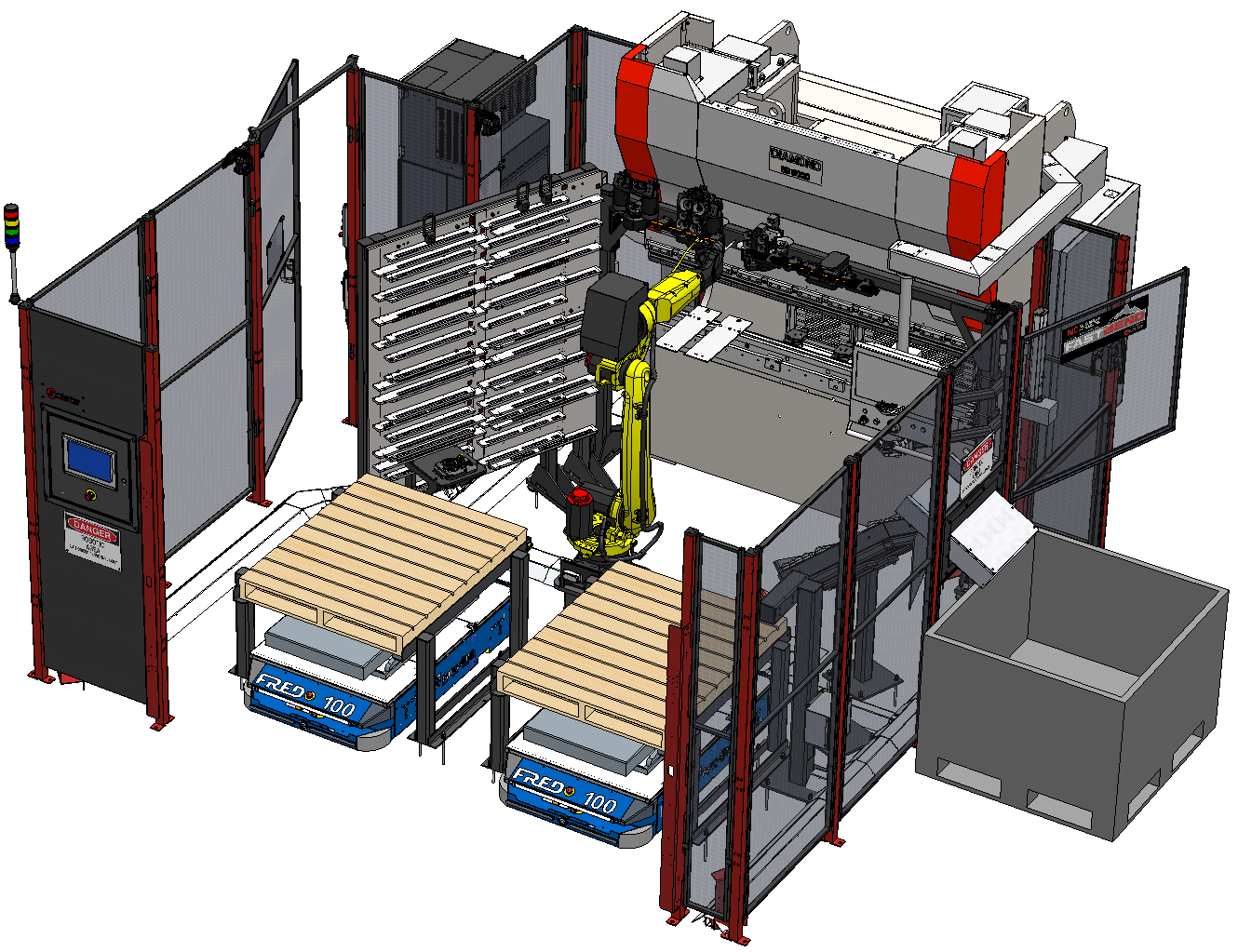

Acieta FastBend Robotic Bending Cell

The Acieta FastBEND bending cell pairs the speed and repeatability of the Diamond BB Series of electric brakes with the industry’s top robotics and automation. The result is a capable and flexible automated bending solution ready for lights out operation.

The FastBEND is made for small to medium parts and mid-to high-volume production, with the capacity to handle greater part weights and sizes than similar cells. Mitsubishi’s partnership with Aceita in brake robotics provides all the benefits of an integrator solution like robotics from Fanuc and full cell customization with the ease of single source support and service from Mitsubishi.

FastBEND Features

Cell Specs and Customization

- Diamond BB 6020 brake (60 tons x 6′ 6″). Diamond brakes are dead nuts accurate and lighting quick. No better brake for a lights out cell.

- Fanuc M20D robot. Benefit from the top robotics supplier in industry with the greatest service coverage.

- 24″ x 36″ x 19.7lb blank capacity. Heavier and larger parts than similar sized cells.

- Tool changing standard. Cell includes tool change gripper and automatic EOAT changing. Multiple EOAT available

- 187″ x 200″ cell footprint. Compact layout maximizes productivity in small package

- Flexible infeed-outfeed. Standard cell includes infeed and outfeed pallets, outfeed pin. Further outfeed bins, AGV integration, conveyors available.

- RoboWave Software. Program computes tool set-up, bend sequence, and robot movements. Faster from office to the floor.

Get in touch with us about your shop’s part mix and automation goals. While we offer the FastBEND as a standard cell, we are happy to work with you to design a bending solution that hits all your needs.