Single Source Fiber Oscillator

The oscillator is the engine of a fiber laser. So while this big box on the side of your machine may be easy to overlook when all is running smoothly, what’s going on inside makes or breaks a fiber laser’s performance, reliability, and the long-term cost of ownership. Unlike other laser vendors that use third party solutions for their oscillators, Mits built theirs from the ground up. A single source Mits oscillator simplifies service and brings innovative internal design features that ensure consistent performance.

Building the Industries Best Resonator : From CO2 to Fiber

When CO2 lasers were the top technology, Mitsubishi had the best. This isn’t just sales speak, the patented Mits cross-flow CO2 was dramatically cheaper to own and operate, required a fraction of the laser gas and needed no refurbs. Mitsubishi’s innovation in resonator technology is a big reason so many of our CO2s remain in operation today.

Mits set that same benchmark of reliability and performance when building their own fiber oscillator. The specifics can get technical quick, but the bottom line is a Mits fiber includes extra safeguards to ensure the most important part of your lasers holds up. Mitsubishi backs this up with an unmatched warranty and best in the industry single-source service.

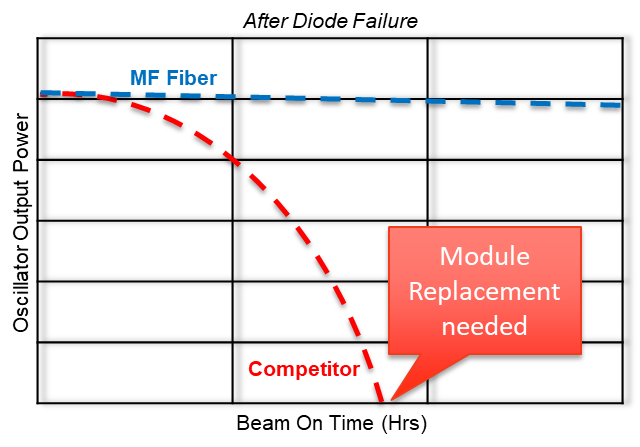

Power in Reserve

Fiber oscillators use a series of diode “modules” that generate power for the laser beam. Different brands use 1 or 2 kw modules, with higher power lasers having more modules. As fiber lasers age, diodes and modules gradually lose output, leading to a loss in overall power. The Mits oscillator includes additional diodes that can be accessed as needed to keep the laser running at full wattage far longer than competitors machines. Its like having a spare tire built into the machine. With competitors machines, power loss is your problem five years after you bought the machine, but not with a Mitsubishi.

Longer Module Life

Induvial diodes that make up an oscillator module will eventually fail. Traditionally, these small failures can lead to a chain reaction that takes out all the diodes on a module board – turning your 10kw fiber into an 8kw in an instant. When Mits designed the GX-F series oscillator, they structured the diodes to run in parallel, meaning a single failure won’t take out a whole string. This sounds like common sense, but other vendors still rely on the old vulnerable design.

Single Source Service and Support

No one wants to hear “that’s not my job”, especially when you are down. But a lot of other laser brands will kick you over to their oscillator vendor for related service. With a Mits fiber, you have one number to call. Under the hood it’s all Mitsubishi too, and that’s the case for the rest of the laser and Mitsubishi automation. This means Mits service can skip wasted time getting parts from other suppliers and can get you a fix and a tech faster. The company’s North American service headquarters is just over the border in Northern Illinois.