Advanced Gas Reduction (AGR)

An air shroud protects and guides the flow of N2 into the kerf, reducing N2 consumption by 1/3rd on average.

AGR initially debuted as a patented nitrogen savings technology in the GX-F. AGR cuts nitrogen consumption by 30%, with even bigger savings in thicker material, all without sacrificing sheet utilization or increasing head crashes. The system uses the GX-F’s dual assist gas ports, an air compressor kit, and specially-designed AGR nozzles to shroud the N2 assist gas.

AGR was an immediate hit, helping our customers reduce the largest operating cost of a fiber without compromising quality. Building on this success, Mits developed new applications for AGR, using the same compressor system to deliver better and more cost effective air cutting, mixed-gas, and O2 cutting conditions.

What began as a tool for reducing Nitrogen consumption now has applications for nearly all materials and shops with no extra equipment.

AGR Components

AGR Nozzles

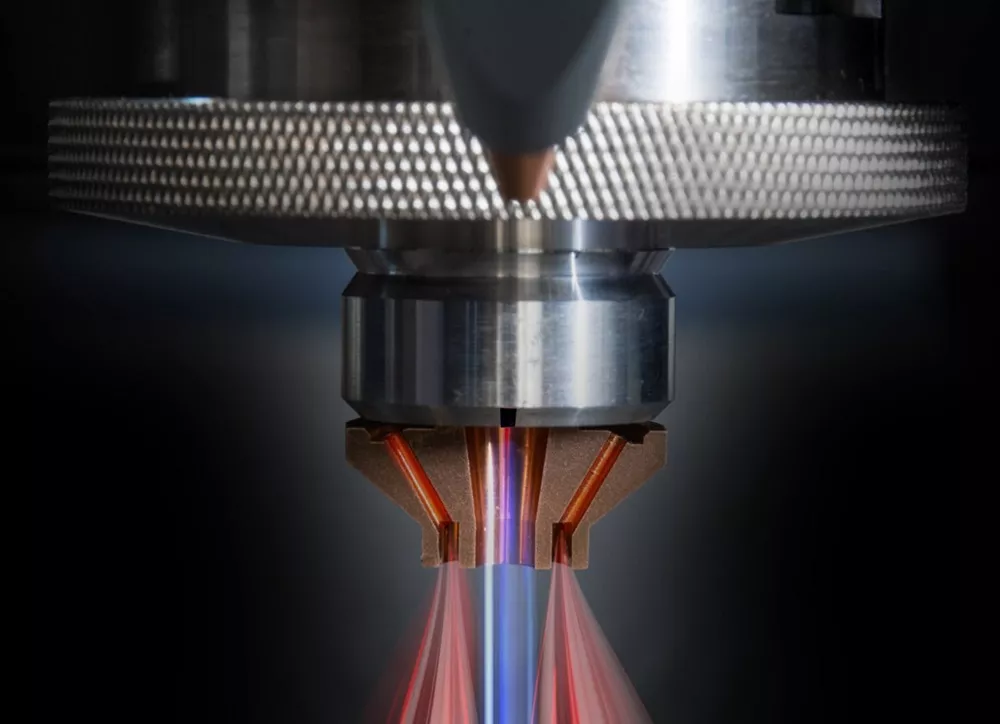

AGR nozzles enable dual gas use, gas mixing, and nozzle cooling.

AGR compressor

Compressor systems designed for the original AGR-N2 also support O2, Air, and Mixed gas applications.

GXF gas box

Advanced and Plus model GX-F's are AGR ready, utilizing the machines dual gas ports and plumbing.

AGR-N2

Competitors gas reduction solutions require crash-prone touchdown nozzles and wider nesting. Not so with AGR.

With AGR-N2, an air curtain surrounds the nitrogen assist gas, forcing it into the kerf where it’s needed and preventing it from blowing across the sheet. N2 consumption on carbon is reduced by 1/3rd, more than 50% on thicker stainless. AGR does not impact speed or edge quality and leaves zero oxide.

AGR-Mix

AGR-Mix is another option for N2 cost savings, edge quality improvements, and easier part denesting.

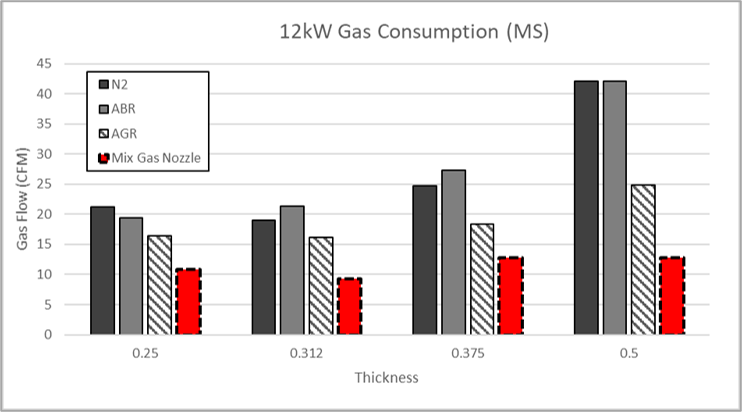

AGR-Mix both shields the flow of N2 assist gas with an air shroud, while also blending a small percentage of air with the flow of N2. The resulting 95% N2, 5% O2 gas blend achieves dramatic (60+% in 3/8″) gas savings compared to straight N2 cutting, and provides more stable processing for reduced burr in mild steel.

AGR-Air

AGR-Air uses the same AGR compressor system that creates the air shroud to supply clean air for use as the laser assist gas. Air cutting has grown in popularity for processing gauge materials and aluminum, with a similar burr to N2. Not every customer will be OK with the oxide, but for the right jobs and materials, AGR-AIR provides an economical assist gas alternative built right into the AGR system.

AGR-O2

The speed advantage of a higher wattage fiber laser’s has traditionally been limited to nitrogen cutting. For oxygen cut parts in plate, or jobs that don’t require an oxide free edge, the feedrate of a fiber didn’t add much over an old CO2. AGR-O2 changes this equation, bringing true fiber speed to thick plate oxygen cutting. AGR-O2 uses the AGR compressor to circulate air in the nozzle. This allows cutting plate 100’s of inches per minute faster than previously possible.