Lasers

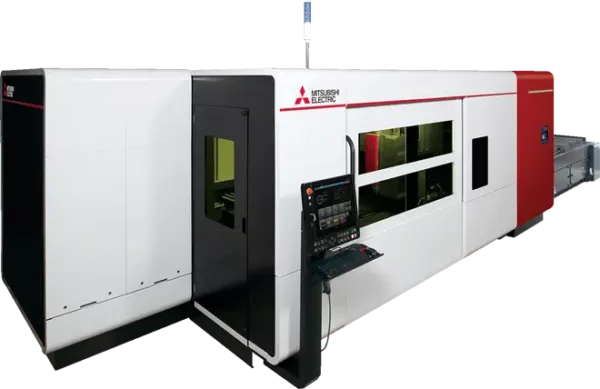

GX-F Series

Mitsubishi’s GX-F series fiber lasers pack speed and power, but they also feature improved edge quality and lower nitrogen usage compared to other fibers, resulting in better parts with reduced operating costs. These lasers are user-friendly, featuring intuitive touch-screen controls and assistance functions that make running a GX-F easy for new and experienced operators alike. Across wattages and models, the GX-F line uses a single source Mits oscillator for more stable cutting and is built with Mitsubishi’s standard for durability. Speed, reliability, lower operating costs, and improved edge – the GX-F series has a model and wattage for any type of shop.

FV 5-Axis Series

The Mitsubishi FV fiber laser combines a double-rail gantry motion system and 4.0G H-axis acceleration for unmatched speed and precision in cutting. Access and fixturing flexibility are key for 5-axis machines, and the FV delivers on both, with a split design table and overhead access for large parts. All major components, including the oscillator and frame are made by Mitsubishi, ensuring seamless service and support from a single source. The FV integrates Mitsubishi’s latest advancements in machine design, CNC control, and automated material handling technologies, offering the fastest processing in Mitsubishi Electric’s history.

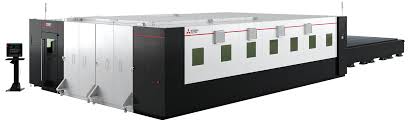

GXL-F Series

The GXL-F fiber laser brings the same edge quality, speed, and cost savings technologies Mitsubishi introduced with the GX-F to a large table machine. Available in 10′ x 20′ and 10′ x 26′ bed sizes, the GXL-F is the prefered machine for some of the countries largest steel service centers. A big bed accommodates wide, or irregular workpieces, reducing the need for additional fabrication, bending, and welding. The unique 10 foot width also means the machine can be loaded with 8 standard 5 x 10 sheets, for hours of unattended cutting between larger jobs.