Profitability in a production environment depends on getting the most parts out the door with the fewest workers and machines on the floor. Automation is key in attaining this goal.

But some fabricators find it difficult to justify the cost of laser automation, or question whether throughput is really any better than what they get from plain old shuttle tables. Here is what customers who own Mitsubishi automation tell us.

More Throughput, Even During Manned Shifts – an automated laser puts out more parts than a manual laser, regardless of whether there is an operator standing next to the machine or not. One owner likened his system to an assembly line. Whoever schedules the automation (i.e. management) sets the pace. Not the operators.

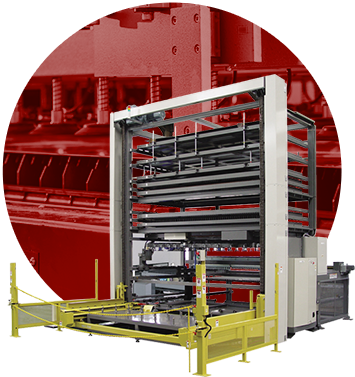

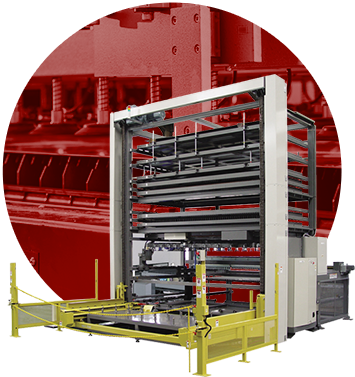

Unmanned Production – all of our customers cut unmanned to some extent. Someone might have the responsibility to reload the tower or unload carts as needed. Or it could be a totally lights-out situation on evenings and weekends, perhaps to take advantage of lower utility rates.

Fewer Lasers Needed – several customers have reduced their overall number of lasers after adding automation, while still increasing throughput.

Fewer Operators – due to fewer machines, and/or the ability to run unmanned.

Automation for Short Runs? – yes. The majority of our customers are job shops.

A Must for Fiber Lasers – fibers are so fast on lighter gauge work that you need automation to keep up. It makes no sense to buy a fast laser if it’s going to sit idle a good share of the time.