Mitsubishi’s partnership with Astes4 is pushing laser automation to provide more functionality with less equipment, offering a fully integrated all-in-one solution from loading material to picking and sorting parts. The 4 in Astes4 makes reference to the patented configuration of four independent gripper heads spanning two gantries, a design that allows for incredible flexibility and efficiency. Like all other Mitsubishi Automation, Astes4 systems are available in configurations and capacities that match with your production demands and are ready to grow.

Truly taking advantage of today’s faster lasers and improved software requires an automation solution that keeps up. Mitsubishi’s answer: the SmartFlex Rapid Series Automation, sporting an industry leading 52 second cycle time (3015). The Rapid Series’s unmatched speed and expandability opens the door to confidently grow and service a multi laser line. Dramatically increase throughput while keeping operating costs low.

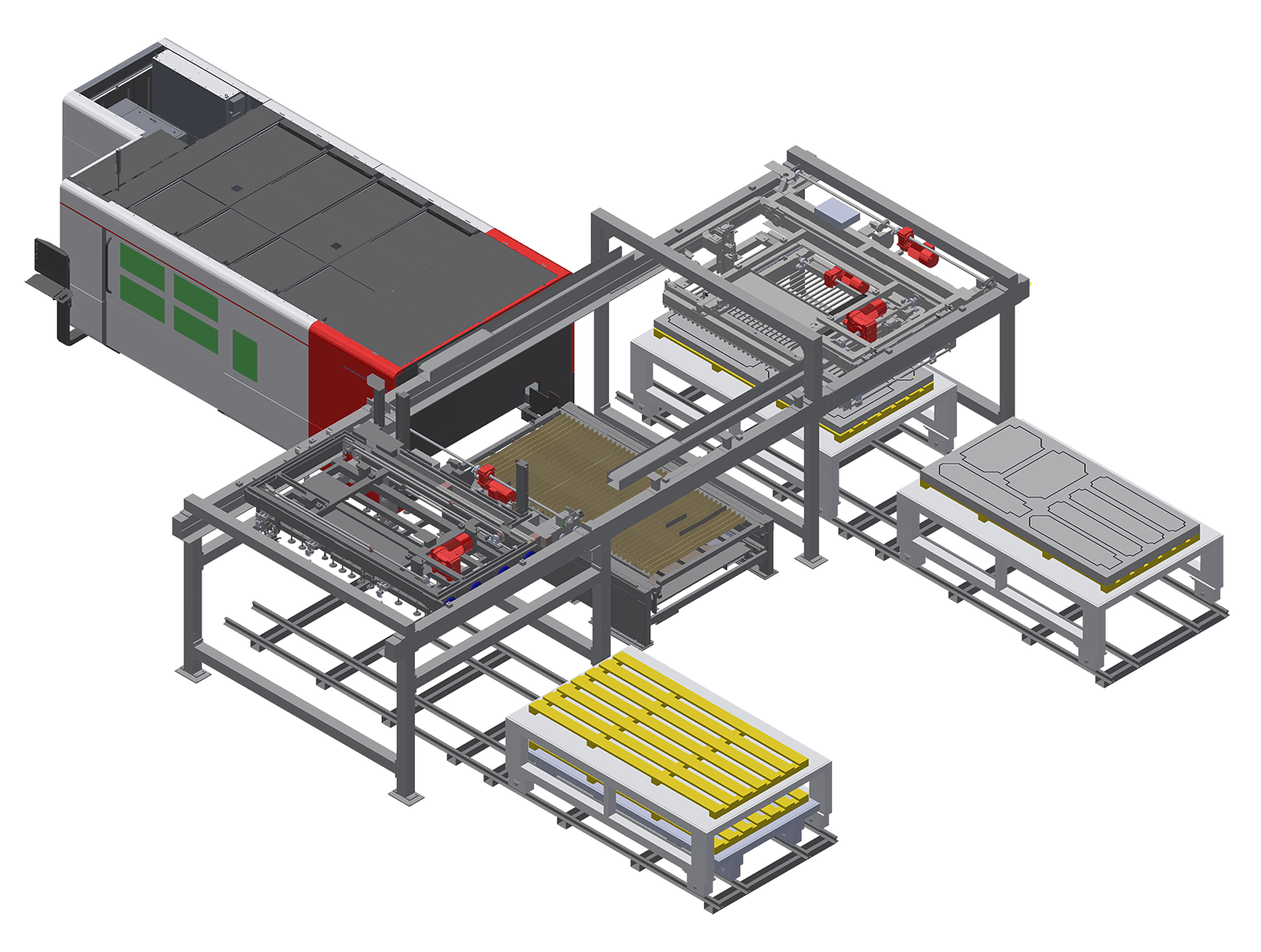

The Rapid Base features two independent over-under shuttle carts for raw material, and two for completed nests. Unlike dual-cart cells (with just one material and one nest cart), the Rapid System remains in operation even when changing raw material pallets or removing nests. As the base system in the Rapid series, seamlessly expand with the addition of a tower and additional lasers. And what you end up with would be identical to a turn-key multiple laser line.

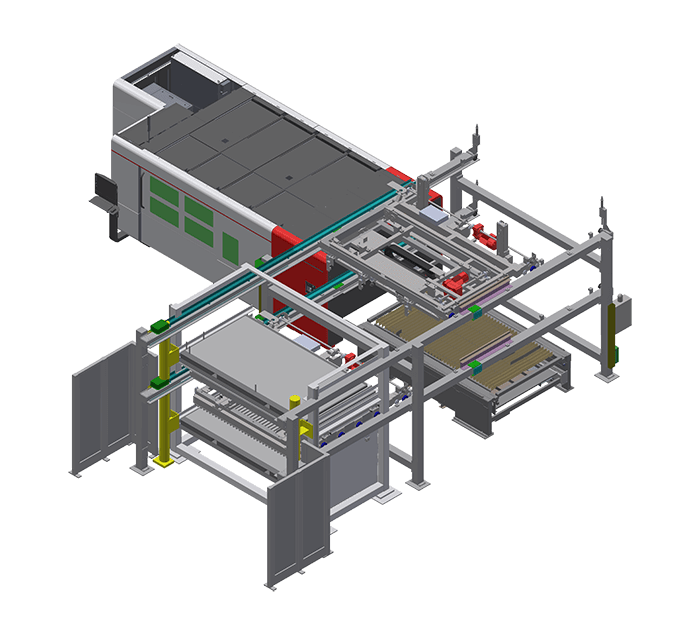

The Rapid tower is Mitsubishi’s most popular automation configuration. Most owners go on to add a second laser to their line. If you’d like a system to be able to expand as your throughput needs grow, a Rapid tower system is for you.

Laser Automation is crucial in a high production fabrication environment. Mitsubishi designed the Element Type R to unlock the benefits of automation for shops with limited space. Despite its compact footprint, the SmartFlex Element boasts impresive specs. and the flexibility to expand.

The SmartFlex Element Type R boosts production while maintaining unrestricted access to the laser and shuttle table. You can run hot jobs and drop-cut parts, then easily transition back to automated production. A great fit for shops needing flexibility and high productivity with limited space.

Building off of the innovative Element Base, the Element Type R Warehouse further expands the benefits of automation in a compact footprint. The inclusion of a material tower holding up to fourteen shelves makes true lights out manufacturing and high-volume, quick turnaround, production possible in shops with limited space.

A streamlined operation is flexible as well as fast, and the Compact Plus automation system provides both. Most automated systems from Mitsubishi have the popular “flow-through” architecture, with raw material on one side and cut nests going to the other. But sometimes this layout is not possible or desirable. For such situations Mitsubishi offers the flexible Compact Plus system.

The Compact base is a purpose-built load/unload with full 1” thickness capability within a 32’x36’ footprint (3015). Mitsubishi Automation is designed to grow with your business, and the Compact Plus is a perfect cornerstone.

The Compact Tower system is available in a number of configurations, meaning our automation can excel in applications and spaces competitors’ systems can’t manage. Offload back to the tower, optional carts, a conveyor, or a dedicated nest tower. The added storage capacity of a tower opens up the possibility for hours of unmanned production.

An automation solution with virtually unlimited storage capacity, the River System is fully customizable to fit a shop’s specific needs and maximize workflow efficiency. A River system streamlines production by eliminating nonvalue-added activities associated with inventory control and administration. The system can be installed as a stand-alone rack supplying material to nearby work stations, integrated with Mitsubishi lasers for lights out operation, or perform both functions. All River systems are configured specifically for a customer’s unique space and application.

Mitsubishi can also customize other systems within the automation lineup, or in some cases design an entirely new system. For example, one Wisconsin customer had Mitsubishi design a system that automatically removes nest skeletons from its dual laser line. They go right out the building and into a dumpster. If you have a special application or goal, Mitsubishi is ready to listen!

Mitsubishi sells a higher percentage of lasers with automation than any other manufacturer. Here’s why:

It Works – There are over 80 automated lasers in operation in Wisconsin alone. Most owners add a second laser to their line, or go on to purchase additional systems.

It’s Fast – What good is a fast laser if your loader can’t keep up? That’s not an issue with Mitsubishi automation. A Mitsubishi tower can even keep pace with multiple lasers cutting different materials, a task many can’t handle.

Built to Last – .030” to full-sheet, 1” load/unload capacity. Some owners who bought their systems years ago are already on their third set of lasers.

Modular – Install automation right off the bat, or add it later. What you’ll end up with will be identical to a turn-key system. Trade up for new lasers while keeping the automation in place.

Fast Retrofit – If adding automation means weeks of laser downtime, most will never do it. Mitsubishi has retrofitted hundreds of lasers and has the process down pat.

Ncell Shop Floor Line Control – Created by the leaders in production automation software, works with any offline nesting software

Auto Cardboard Layering – Cosmetically sensitive stainless nests, even those with a pvc covering, can get marred as they stack on a cart. This unique feature prevents this from occurring.