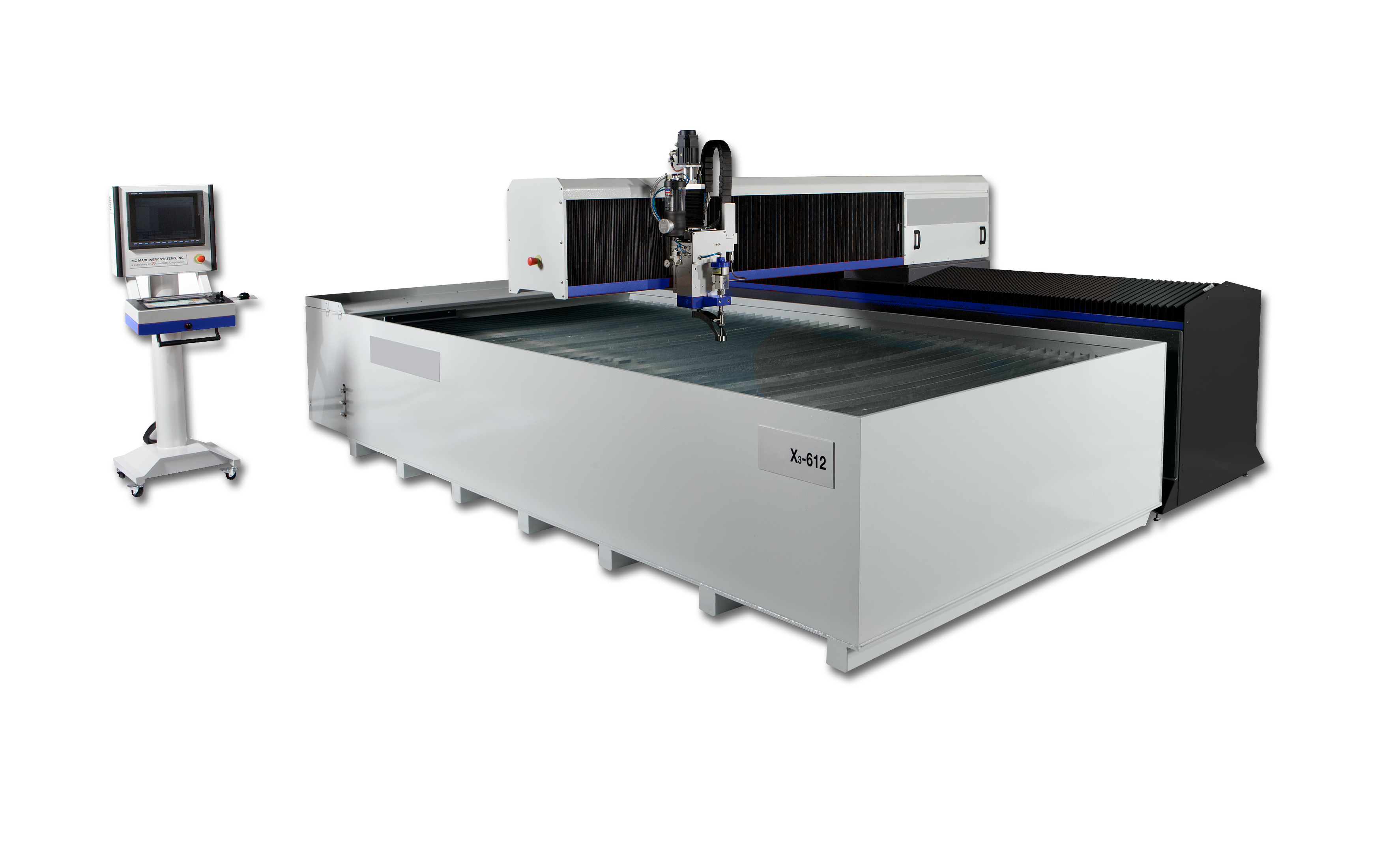

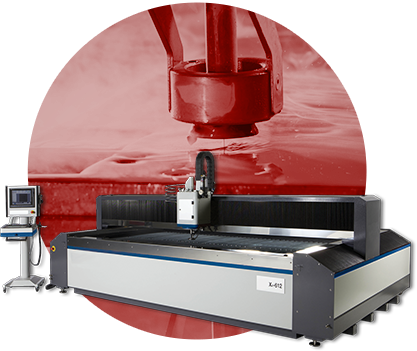

AKS WATERJET

Quality and Versatility for Shops that Do It All

Every machine designed and sold by Mitsubishi is built to help you do more high-quality work, easier. For customers with cutting applications that don’t require a laser we have partnered with AKS to make this high standard a reality for water jets. AKS made their name building the nicest table, drive system, and beveling head in the plasma field. Over a century of experience crafting precision equipment in the U.S. has made AKS an industry leader in precision and durability innovation. Paired with Mitsubishi CNC controls and drives, AKS waterjets offer precision and quality not available in any other waterjet on the market.